Mandatory deposit on containers in Germany

The Bundesrat (upper house of German parliament) recently voted in favor of extending the mandatory eolith on containers to cover all non-returnable plastic bottles and beverage cans. This is proficient news for the protection of the environs. Besides yielding a higher quota of returns, a high recycling rate positively impacts the eco-residue of beverage packaging. Notwithstanding, implementing this would present a lot of juice producers with several challenges. Their trouble is that most plastic bottles filled with sensitive products such as juice cannot exist collected by type and recycled to brand new bottles due to the limerick of their materials. Barrier technologies already established on the market provide an answer here; these protect the liquid food from the gas substitution with the help of a wafer-thin layer of chemically pure glass. Dortmund manufacturer of filling and packaging systems KHS is a pioneer in this field. Since 2002 the corporate group has provided a glass coating engineering science that enables full bottle-to-bottle recycling under the name of FreshSafe PET.

Plastic bottles should be returned to a deposit machine. Yet, as is so oft the instance, unfortunately, there are exceptions to this rule. While a deposit is levied on apple spritzer in non-returnable PET bottles, at that place is no such obligation for apple juice in the same packaging type. Juice bottles are thus collected through dual waste disposal systems and cannot exist recycled to brand new Mandatory deposit on containers in Germany. PET bottles in the sense of a circular economy. For consumers, this dominion is confusing.

Regarding the protection of the environment, likewise, the current legislation is also difficult to fathom. Due to the limitations of the mandatory deposit system, about 10% of all PET bottles each year are lost to the closed recycling loop, according to a study by packaging market research constitute GVM from 2018. This amounts to approximately 40,000 metric tons of plastic per annum that cannot be reused to brand food packaging. The German federal land of Hesse has since recognized this problem and, together with Baden-Württemberg, practical to widen the telescopic of the compulsory deposit on potable containers in the upper house of the German parliament – with success. This recently voted in favor of extending the mandatory deposit system to cover all non-returnable plastic bottles.

Juice bottles: the problem of recyclability

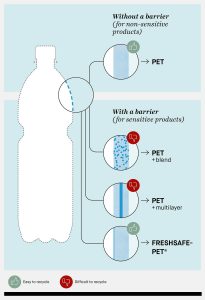

KHS said this recommendation causes concern to many German language juice producers who fill their products into non-deposit one-manner PET bottles. Different water or many carbonated soft drinks, these sensitive beverages have to be protected confronting external influences such every bit oxygen pickup. To ensure this protection, juice and nectar bottles fabricated of PET ofttimes comprise additives with oxygen absorbers. These additives make them more difficult to recycle than a normal PET bottle. Despite being subjected to elaborate processes, the various materials cannot be separated during recycling and cause discoloration of the recyclate, for instance. This complicates pooled recycling with the conventional non-returnable PET containers in the eolith organization and renders global bottle-to-canteen recycling, for which 100% pure rPET is required, practically incommunicable.

According to KHS, one environmentally-friendly alternative is to use an oxygen barrier made of chemically pure drinking glass. The wafer-sparse coating on the within of the PET bottle not but effectively protects the juice from oxygen pickup but is also fully recyclable. During the standard recycling procedure, the coating is hydrolyzed using hot caustic and removed from the inside bottle wall. It and so goes into a solution, and the pure PET can exist collected by type.

Bachelor solution

The KHS Group is a pioneer in the field of interior drinking glass coating for PET bottles. For about 15 years at present, the systems manufacturer and packaging specialist has offered its customers a fully recyclable system for juice bottles in the food and beverage industries. Bottlers of renown such every bit Eckes-Granini have been using the eco-friendly packaging organization named FreshSafe PET for many years.

The manufacture of the recyclable PET bottle differs only slightly from that of a conventional juice bottle. In both cases, a standard PET preform is used as the basic cloth. These plastic containers that await similar a test tube with a screw pinnacle are turned into bottles on a stretch blow molding machine. Here, the preform can be made of new plastic or of recycled material – or what is known as recyclate.

In the FreshSafe PET arrangement, the canteen is so fed to a downstream blanket car. KHS provides this in several dissimilar versions and with various capacity ranges. The KHS InnoPET Plasmax 20QS, for example, outputs upwardly to 48,000 bottles per hour. The turnkey supplier's extensive portfolio also includes two compact block systems. The InnoPET FreshSafe block linked upward to a KHS stretch blow molder produces empty coated PET bottles. The KHS InnoPET FreshSafe TriBlock comprising a stretch blow molder, coating auto, and filling unit blows, coats, and fills the bottles on a single auto before these are so sealed.

From pharmaceuticals to food and beverages

The bottles are coated using the Plasma Impulse Chemical Vapor Deposition (PICVD) method, a process first used in the pharmaceutical manufacture. In this process, a reaction gas mixture is introduced into the PET canteen in a fine vacuum, and this is subsequently transformed into a plasma land by microwaves. In this land, SiOx or chemically pure glass, is deposited on the within of the bottle.

The interior glass blanket is transparent and has a thickness of less than 0.i µm. It is thus flexibly and chemically bonded to the inside wall of the juice bottle. KHS said this prevents the glass coating from existence accidentally removed when forcefulness is applied to the PET bottle; for instance, it can only be separated during the recycling process. Due to this detail holding, the FreshSafe PET bottle from KHS is 100% bottle-to-bottle recyclable. This has besides been recognized by merchandise associations such as the European PET Bottle Platform and the Association of Plastic Recyclers (United states). Furthermore, the bottle's suitability for utilize with foods has also been officially proven. In many countries, including the United states and Europe, the KHS arrangement has food-class approval.

FreshSafe PET has many benefits

KHS said after coating the FreshSafe PET bottle can exist filled with production and provides full protection against both oxygen pickup and loss of CO2 and water vapor. In this way, the Plasmax coating prevents the sensitive beverage's quality from being compromised and means that the production keeps up to ten times longer than in uncoated plastic bottles.

In addition, glass-coated PET juice bottles have several further benefits for the consumer and the environment. For instance, plastic bottles are much lighter than glass bottles. This positively impacts the amount of CO2 emitted by trucks as fewer bottles, or lower load weights mean less gas consumption. Plastic bottles are also unbreakable and flexible.

In addition to environmental aspects and the protection of the product, the economy is too essential. On the ane paw, due to the glass coating, the amount of plastic used compared to containers with oxygen absorbers is lower, thus yielding cost savings. On the other, bottlers tin can work with standard PET preforms, further reducing the cost per canteen.

KHS promotes the closed recycling loop

According to KHS, the FreshSafe PET system's advantage, however, lies in its ability to be fully recycled to produce pure PET. With this, the KHS Group supports efforts to create a closed PET recycling loop and facilitate bottle-to-bottle recycling. This is essential if plastic bottles have a positive eco-residue, as the ALPLA LCA Packaging report carried out last year illustrates.

To continue to boost the high recycling rate of nigh 93% for PET bottles in Germany and farther strengthen the canteen-to-bottle recycling loop, the KHS Group recently introduced an innovative canteen concept for sensitive beverages. Its Beyond Juice canteen is a fully recyclable PET bottle made entirely of recycled materials. Due to the FreshSafe PET barrier system, it provides outstanding production protection. Ecology service provider Interseroh has issued the container with its Made for Recycling seal of quality. KHS said that the Beyond Juice bottle is the first PET bottle e'er to score a full twenty out of twenty points in this rating system.

KHS stated with the new canteen concept, juice producers can save more than than 1,500 metric tons of raw materials at a production of fifty 1000000 bottles a twelvemonth. In doing so, they are helping to improve the eco-remainder of plastic packaging. The Across Juice canteen is fifty-fifty more than environmentally friendly in combination with Nature MultiPack from KHS. This container system holds bottles together with dots of adhesive, which are stiff and secure nevertheless easy to remove. With the help of this tried-and-tested packaging variant, the plastic film otherwise used to form PET bottles into packs of six, for case, is no longer required. This claims to reduce the corporeality of packaging waste by upwards to ninety%. Like the coated PET juice bottles, the dots of agglutinative are also fully recyclable.

KHS in India

With its headquarters and manufactory in Ahmedabad, Gujarat, West India, on a production site of 18,000 square meters, KHS Machinery plays a pregnant part in supplying the KHS portfolio to customers from India and Southeast Asia. KHS Bharat started as a joint venture, with 60% ownership of KHS Germany. Over the years, it increased its share to more than 95% today but likewise helped expand the pie. The company, which was created to cater just to the Indian marketplace, slowly spread its wings and started exporting to markets in Southeast Asia, Red china, and Australia with the support of KHS Germany.

Source: https://packagingsouthasia.com/application/mandatory-containers/

0 Response to "Mandatory deposit on containers in Germany"

Post a Comment